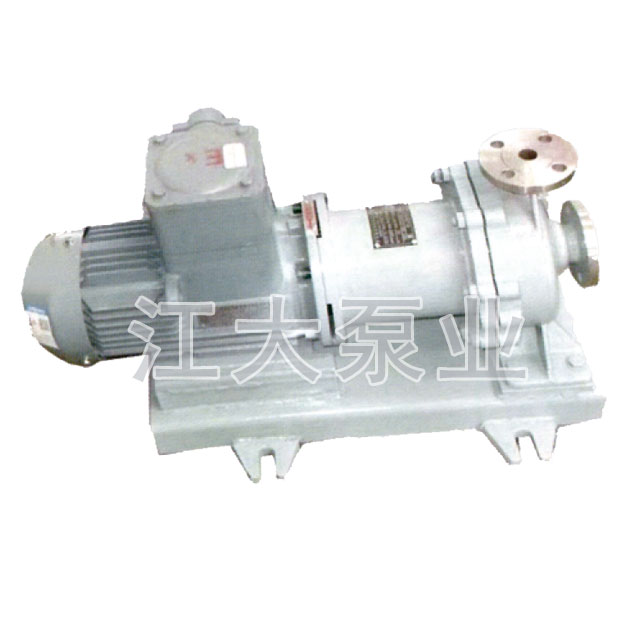

江大泵业

Product Categories联系我们

江苏江大泵业制造有限公司

电话:4000800806

邮箱:jsjdby@126.com

地址:江苏泰兴市虹桥工业园区

一、概述

THR型热水循环泵是单级单吸(轴向吸入)离心泵,供输送不含固体颗粒、粘度类似水的液体。介质温度为-20℃~300℃,根据工艺需要可配合采用冷却措 施。适用于石油、化工、冶金、电力、造纸、食品、制药和合成纤维等行业。

二、性能范围

性能范围: 流量Q:5-800m3/h

扬程H:5-100m

泵型号 Type | 流量Q Capacity | 扬程 H Head (m) | 转速 N Speed (r/min) | 功率Power(k w) | 效率 η Efficiency (%) | 必需汽蚀 余量 (NPSH) (m) | ||

(m3/h) | (L/S) | 轴功率 Shaft | 电机功率 Motor | |||||

THR40-32-125 | 6.3 | 1.74 | 20 | 2900 | 0.66 | 1.5 | 48 | 5.0 |

THR40-32-160 | 6.3 | 1.74 | 32 | 2900 | 1.53 | 2.2 | 36 | 3.5 |

THR40-32-200 | 6.3 | 1.74 | 50 | 2900 | 2.52 | 4 | 34 | 3.5 |

THR40-32-250 | 6.3 | 1.74 | 80 | 2900 | 5.3 | 7.5 | 26 | 4.5 |

THR50-32-125 | 12.5 | 3.47 | 20 | 2900 | 1.33 | 2.2 | 51 | 2.0 |

6.3 | 1.74 | 5.0 | 1450 | 0.19 | 0.55 | 45 | 1.0 | |

THR50-32-160 | 12.5 | 3.47 | 32 | 2900 | 2.37 | 3 | 46 | 2.0 |

6.3 | 1.74 | 8.0 | 1450 | 0.34 | 0.55 | 40 | 1.0 | |

THR50-32-200 | 12.5 | 3.47 | 50 | 2900 | 4.36 | 5.5 | 39 | 2.0 |

6.3 | 1.74 | 12.5 | 1450 | 0.65 | 1.1 | 33 | 1.0 | |

THR50-32-250 | 12.5 | 3.47 | 80 | 2900 | 8.25 | 11 | 33 | 2.0 |

6.3 | 1.74 | 20 | 1450 | 1.27 | 1.5 | 27 | 1.0 | |

THR65-50-125 | 25 | 6.94 | 20 | 2900 | 2.2 | 3 | 62 | 2.0 |

12.5 | 3.47 | 5 | 1450 | 0.31 | 0.55 | 55 | 1.0 | |

THR65-50-160 | 25 | 6.94 | 32 | 2900 | 3.82 | 5.5 | 51 | 2.0 |

12.5 | 3.47 | 8 | 1450 | 0.53 | 0.75 | 51 | 1.0 | |

THR65-40-200 | 25 | 6.94 | 50 | 2900 | 6.55 | 11 | 52 | 2.0 |

12.5 | 3.47 | 12.5 | 1450 | 0.93 | 1.5 | 46 | 1.0 | |

THR65-40-250 | 25 | 6.94 | 80 | 2900 | 11.84 | 18.5 | 46 | 2.0 |

12.5 | 3.47 | 20 | 1450 | 1.75 | 3 | 39 | 1.0 | |

THR65-40-315 | 25 | 6.94 | 125 | 2900 | 21.8 | 30 | 39 | 2.0 |

12.5 | 3.47 | 32 | 1450 | 3.3 | 4 | 33 | 1.0 | |

THR80-65-125 | 50 | 13.9 | 20 | 2900 | 3.95 | 5.5 | 69 | 3.0 |

25 | 6.94 | 5 | 1450 | 0.53 | 0.75 | 64 | 1.5 | |

THR80-65-160 | 50 | 13.9 | 32 | 2900 | 6.5 | 11 | 67 | 2.3 |

25 | 6.94 | 8 | 1450 | 0.88 | 1.5 | 62 | 1.1 | |

THR80-50-200 | 50 | 13.9 | 50 | 2900 | 10.8 | 15 | 63 | 2.5 |

25 | 6.94 | 12.5 | 1450 | 1.49 | 2.2 | 57 | 1.1 | |

THR80-50-250 | 50 | 13.9 | 80 | 2900 | 20.6 | 22 | 53 | 2.5 |

25 | 6.94 | 20 | 1450 | 2.72 | 4 | 50 | 1.2 | |

THR80-50-315 | 50 | 13.9 | 125 | 2900 | 34.1 | 45 | 50 | 2.5 |

25 | 6.94 | 32 | 1450 | 4.54 | 7.5 | 43 | 1.0 | |

THR100-80-125 | 100 | 27.8 | 20.0 | 2900 | 7.47 | 11 | 73 | 4.2 |

THR100-80-160 | 100 | 27.8 | 32 | 2900 | 11.9 | 15 | 73 | 4.3 |

50 | 13.9 | 8 | 1450 | 1.58 | 2.2 | 69 | 2.1 | |

THR100-65-200 | 100 | 27.3 | 50 | 2900 | 18.9 | 22 | 72 | 3.9 |

50 | 13.9 | 12.5 | 1450 | 2.5 | 4 | 68 | 1.8 | |

THR100-65-250 | 100 | 27.8 | 80 | 2900 | 32.0 | 37 | 68 | 3.6 |

50 | 13.9 | 20 | 1450 | 4.3 | 5.5 | 63 | 1.8 | |

THR100-65-315 | 100 | 27.8 | 125 | 2900 | 54.9 | 75 | 62 | 3.2 |

50 | 13.9 | 32 | 1450 | 7.5 | 11 | 58 | 1.6 | |

THR125-80-160 | 152 | 44.4 | 31 | 2900 | 23.3 | 30 | 55 | 5.3 |

THR125-100-200 | 200 | 55.6 | 50 | 2900 | 35.4 | 45 | 77 | 5.0 |

100 | 27.8 | 12.5 | 1450 | 4.66 | 7.5 | 73 | 2.9 | |

THR125-100-250 | 200 | 55.6 | 80 | 2900 | 58.1 | 75 | 75 | 4.5 |

100 | 27.8 | 20 | 1450 | 7.56 | 11 | 72 | 2.3 | |

THR125-100-315 | 100 | 27.8 | 32 | 1450 | 13.5 | 18.5 | 65 | 2.5 |

THR125-100-400 | 100 | 27.8 | 50 | 1450 | 24.8 | 30 | 55 | 2.5 |

THR150-125-250 | 200 | 55.6 | 20 | 1450 | 14.1 | 18.5 | 77 | 2.8 |

THR150-125-315 | 200 | 55.6 | 32.0 | 1450 | 23.2 | 30 | 75 | 2.8 |

THR150-125-400 | 200 | 55.6 | 50 | 1450 | 38.9 | 45 | 70 | 2.5 |

THR200-150-250 | 400 | 111.1 | 20 | 1450 | 29.4 | 37 | 74 | 2.8 |

THR200-150-315 | 400 | 111.1 | 32.0 | 1450 | 44.1 | 55 | 79 | 3.5 |

THR200-150-400 | 400 | 111.1 | 50 | 1450 | 69.8 | 90 | 78 | 3.5 |

订货时需注明使用工况:温度、流量、压力、密度、介质及环境温度、电机要求等事项。

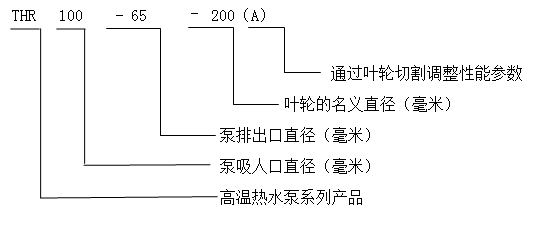

泵型号意义说明举例:

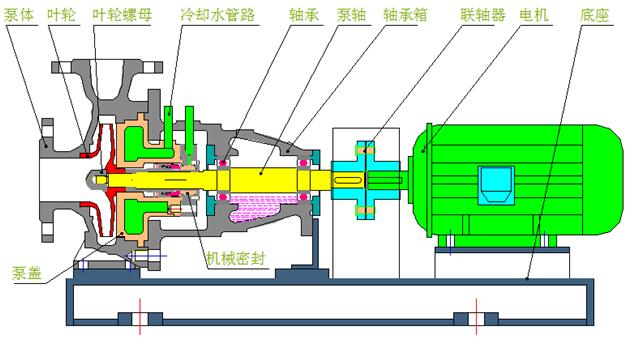

三、结构

THR型泵为卧式径向剖分后开门泵。拆卸、维修简便,不用拆卸泵体、管路,就可进行检修。泵主要由泵体、泵盖、叶轮、轴、机械密封、中间支架和轴承部件等组成。